沸石分子篩轉輪吸附濃縮的廢氣處理介紹

來源:http://www.9qmv.com/ 發布時間:2023-04-12

沸石分子篩轉輪組合為一中心軸承與轉體,是吸附、脫附及濃縮焚化三項操作單元格為一體,且比較完善的設備之一,相對比蜂窩狀的活性炭具有非常多的優勢,兩者在吸附工藝上是相同的,但沸石的吸咐性能遠大于活性炭,如甲醛的去除,活性炭吸附基本使用周期小于一年,很容易吸附飽和定期需要更換,沸石轉輪分子篩使用年限可以達到10年以上,在資金和更換頻率上大大降低,可降低人力物力的支出,安全性、連續性效率等一次性投資收益幾十年,而且脫附后和催化燃燒階段的有機VOC氣體濃度和效率更高。所以沸石分子篩轉輪被越來越多的應用到處理有機廢氣當中。

The combination of zeolite molecular sieve wheels is a central bearing and a rotating body, which is one of the relatively complete equipment for adsorption, desorption, and concentration incineration. It has many advantages over honeycomb activated carbon in terms of adsorption process, but the adsorption performance of zeolite is much greater than that of activated carbon, such as the removal of formaldehyde. The basic service life of activated carbon adsorption is less than one year, It is easy to adsorb and saturate, and it needs to be replaced regularly. The service life of zeolite rotary molecular sieve can reach more than 10 years, greatly reducing the cost and frequency of replacement, and reducing the expenditure on manpower and material resources. The one-time investment returns such as safety and continuity efficiency can last for decades. Moreover, the organic VOC gas concentration and efficiency in the desorption and catalytic combustion stages are higher. So zeolite molecular sieve wheels are increasingly being used in the treatment of organic waste gas.

沸石分子篩的工藝原理運行方式:

The process principle and operation mode of zeolite molecular sieve:

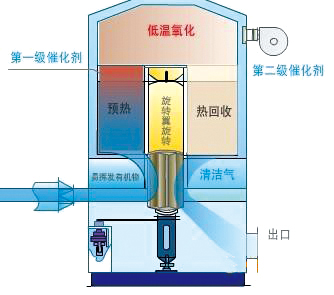

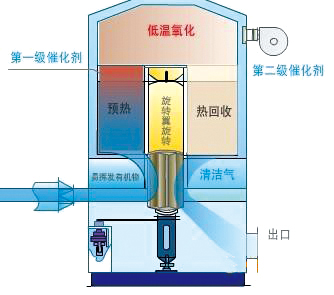

沸石分子篩吸附濃縮轉輪密封系統分為處理區,再生區和冷卻區三個部分,轉輪緩慢旋轉(1~6r/h)使各個區內吸附過程完整連續運轉。當VOCs有機廢氣通過前置處理區時,其中的有機廢氣成分被轉輪中的吸附劑所吸附去除,廢氣被凈化后的空氣從濃縮轉輪的處理區間而排空,轉輪逐漸達到吸附飽和。同時在再生區高溫下空氣通過吸附飽和,廢氣被吸附脫附后由經高溫空氣排走,達到連續去除VOCs效果的同時也恢復轉輪的吸附能力提高廢氣濃度,脫附的高溫氣體進入RTO/CO氧化裝置便于進行氧化處理。

The sealing system of the zeolite molecular sieve adsorption and concentration rotary wheel is divided into three parts: the treatment zone, the regeneration zone, and the cooling zone. The rotary wheel slowly rotates (1-6r/h) to ensure the complete and continuous operation of the adsorption process in each zone. When VOCs organic waste gas passes through the pre-treatment zone, the organic waste gas components are adsorbed and removed by the adsorbent in the runner. The purified air in the waste gas is discharged from the treatment zone of the concentration runner, and the runner gradually reaches adsorption saturation. At the same time, at high temperatures in the regeneration zone, the air is saturated through adsorption, and the waste gas is adsorbed and desorbed before being discharged through high-temperature air, achieving continuous removal of VOCs while also restoring the adsorption capacity of the runner to improve the concentration of waste gas. The desorbed high-temperature gas enters the RTO/CO oxidation device for easy oxygenation treatment.

技術核心:

Technical core:

工藝核心:適用于連續運行場合,旋轉吸附轉輪式的結構,轉速,風速,連續運行沒有偏流的現象,脫附濃度穩定凈化效率高。

Process core: Suitable for continuous operation, with a rotating adsorption wheel structure, rotational speed, wind speed, and continuous operation without bias flow. The desorption concentration is stable and the purification efficiency is high.

材料核心:不燃的無機硅酸鹽為吸附材料,從原材料上消除著火隱患;吸附壽命長(5-10Y);結構強度大,耐水性好;微孔分布豐富,孔道均勻,吸附效率高。

Material core: Non combustible inorganic silicates are used as adsorption materials to eliminate fire hazards from the raw materials; Long adsorption life (5-10Y); High structural strength and good water resistance; Rich distribution of micropores, uniform pore channels, and high adsorption efficiency.

技術優勢:

Technical advantages:

安全性好:吸附材料為無機硅酸鹽,不燃,消除著火隱患;

Good safety: The adsorption material is inorganic silicate, which is non combustible and eliminates fire hazards;

處理高效:凈化效率可達95%,環保達標;

Efficient treatment: The purification efficiency can reach 95%, meeting environmental standards;

運行穩定:吸脫附穩定連續,脫附溫度達200℃;

Stable operation: Stable and continuous adsorption and desorption, with a desorption temperature of up to 200 ℃;

維護費用低:吸附材料壽命長;沒有控制閥;

Low maintenance cost: Long service life of adsorption materials; No control valve;

投資少:濃縮10倍以上,降低后處理設備要求;

Low investment: concentration of more than 10 times, reducing requirements for post-processing equipment;

多種工藝可組合,余熱利用率高:與RTO實現高熱能回收≥95%;與CO組合回收余熱。

Multiple processes can be combined, with high waste heat utilization rate: achieving high heat recovery ≥ 95% with RTO; Combine with CO to recover waste heat.

魯公網安備 37142502000144號

魯公網安備 37142502000144號