車間整體除塵設(shè)備:好好維護(hù)才能延長(zhǎng)壽命

車間整體除塵設(shè)備的正確維護(hù)對(duì)于保持設(shè)備的良好運(yùn)行狀態(tài)、延長(zhǎng)使用壽命以及確保生產(chǎn)環(huán)境的清潔至關(guān)重要。以下是一些關(guān)鍵的維護(hù)步驟和措施:

The correct maintenance of the overall dust removal equipment in the workshop is crucial for maintaining the good operating condition of the equipment, extending its service life, and ensuring the cleanliness of the production environment. Here are some key maintenance steps and measures:

1. 定期檢查:

1. Regular inspection:

檢查除塵設(shè)備的濾袋是否需要更換,根據(jù)壓差計(jì)的讀數(shù)判斷濾袋是否堵塞。

Check if the filter bag of the dust removal equipment needs to be replaced, and determine if the filter bag is clogged based on the reading of the differential pressure gauge.

檢查電磁脈沖閥是否正常工作,無(wú)故障。

Check if the electromagnetic pulse valve is working properly and there are no faults.

檢查氣源處理器中的雜質(zhì)和積水,定期排放。

Check for impurities and accumulated water in the air source processor and discharge regularly.

2. 清潔工作:

2. Cleaning work:

保持設(shè)備內(nèi)外的清潔,特別是風(fēng)機(jī)、電機(jī)等關(guān)鍵部件。

Keep the inside and outside of the equipment clean, especially key components such as fans and motors.

清除設(shè)備周圍的灰塵和雜物,保持通風(fēng)良好。

Remove dust and debris around the equipment and maintain good ventilation.

3. 潤(rùn)滑和加油:

3. Lubrication and refueling:

定期給設(shè)備的傳動(dòng)裝置加油,并注意防塵。

Regularly lubricate the transmission device of the equipment and pay attention to dust prevention.

檢查油水分離器,定期排污。

Check the oil-water separator and regularly discharge water.

4. 緊固件檢查:

4. Inspection of fasteners:

檢查設(shè)備的緊固件是否松動(dòng),及時(shí)緊固。

Check if the fasteners of the equipment are loose and tighten them in a timely manner.

5. 電源線維護(hù):

5. Power cord maintenance:

檢查電源線是否老化,防止短路或漏電。

Check if the power cord is aging to prevent short circuits or leakage.

6. 運(yùn)行監(jiān)控:

6. Operation monitoring:

監(jiān)控設(shè)備的運(yùn)行狀態(tài),如有異常及時(shí)處理。

Monitor the operating status of the monitoring equipment and promptly handle any abnormalities.

7. 停機(jī)維護(hù):

7. Shutdown maintenance:

設(shè)備停機(jī)時(shí),應(yīng)清灰,避免潮氣和粉塵黏糊在袋子上造成設(shè)備故障。

When the equipment is shut down, the dust should be cleaned to avoid moisture and dust sticking to the bag and causing equipment failure.

8. 專業(yè)培訓(xùn):

8. Professional training:

對(duì)車間管理人員和操作人員進(jìn)行定期培訓(xùn),提高維護(hù)技能。

Regularly train workshop managers and operators to improve maintenance skills.

通過(guò)上述措施,可以確保車間整體除塵設(shè)備的長(zhǎng)期穩(wěn)定運(yùn)行,提高除塵效率,同時(shí)也能延長(zhǎng)設(shè)備的使用壽命,降低維護(hù)成本。

Through the above measures, the long-term stable operation of the overall dust removal equipment in the workshop can be ensured, the dust removal efficiency can be improved, and the service life of the equipment can also be extended, reducing maintenance costs.

本文由車間整體除塵設(shè)備提供幫助,更多的相關(guān)內(nèi)容請(qǐng)點(diǎn)擊:http://www.9qmv.com希望本文能夠?yàn)槟鷰?lái)幫助,感謝您的閱讀!

This article is assisted by the overall dust removal equipment in the workshop. For more related content, please click: http://www.9qmv.com I hope this article can be helpful to you. Thank you for reading!

上一篇:

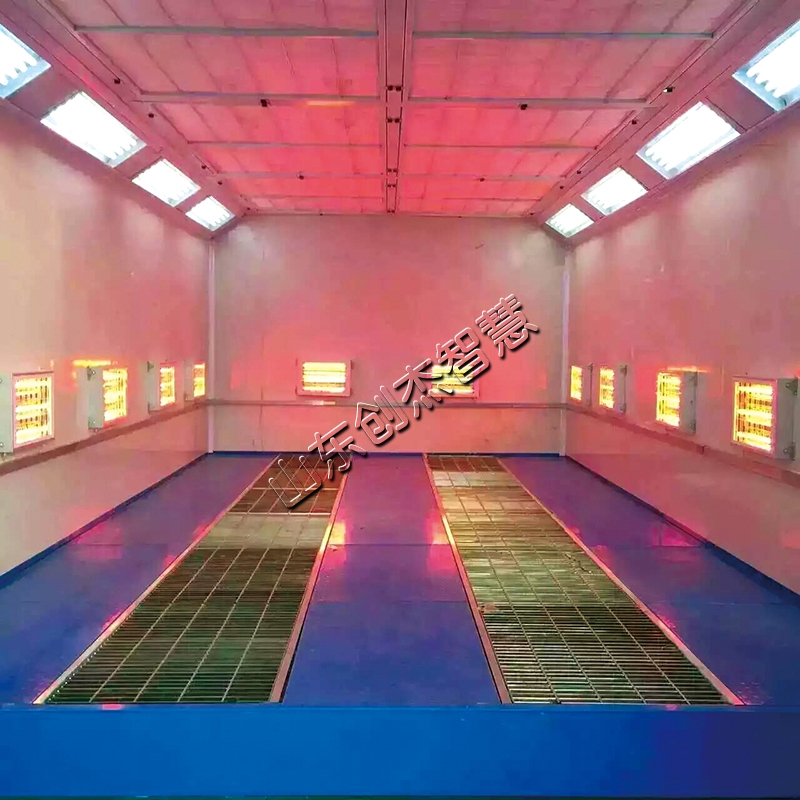

下一篇:環(huán)保伸縮噴漆房在設(shè)計(jì)上要注意什么?

魯公網(wǎng)安備 37142502000144號(hào)

魯公網(wǎng)安備 37142502000144號(hào)