RTO廢氣處理設(shè)備:在焦化VOCs廢氣方面的作用

焦化廢氣含有瀝青煙、苯并芘及苯類等有害物質(zhì),如果直接排放,會(huì)造成大氣污染,影響當(dāng)?shù)氐纳鷳B(tài)環(huán)境。因此,對(duì)焦化廢氣進(jìn)行處理并使其達(dá)標(biāo)排放,是焦化行業(yè)可持續(xù)發(fā)展的必然要求。

Coking waste gas contains harmful substances such as asphalt smoke, benzo [a] pyrene, and benzene. If directly discharged, it will cause air pollution and affect the local ecological environment. Therefore, treating coking waste gas and ensuring it meets emission standards is an inevitable requirement for the sustainable development of the coking industry.

某焦化化工廠是生產(chǎn)苯類、酚類、萘類、樹脂類、鹽類等化工產(chǎn)品為主的煤化工綜合利用企業(yè),焦油加工能力為10萬t/a,苯加工能力為3萬t/a,為合成纖維、油漆、染料、醫(yī)藥、農(nóng)藥、化肥等產(chǎn)品提供了豐富的原料。與此同時(shí),該化工廠在正常生產(chǎn)過程中會(huì)產(chǎn)生溫度為20~50℃、流量為4000~18000m3/h的焦化廢氣,其基本成分及物化數(shù)據(jù)如表1所示。

A certain coking chemical plant is a coal chemical comprehensive utilization enterprise that mainly produces chemical products such as benzene, phenols, naphthalene, resins, salts, etc. The tar processing capacity is 100000 t/a, and the benzene processing capacity is 30000 t/a. It provides abundant raw materials for synthetic fibers, paints, dyes, pharmaceuticals, pesticides, fertilizers and other products. At the same time, the chemical plant produces coking waste gas with a temperature of 20-50 ℃ and a flow rate of 4000-18000m3/h during normal production. The basic composition and physicochemical data are shown in Table 1.

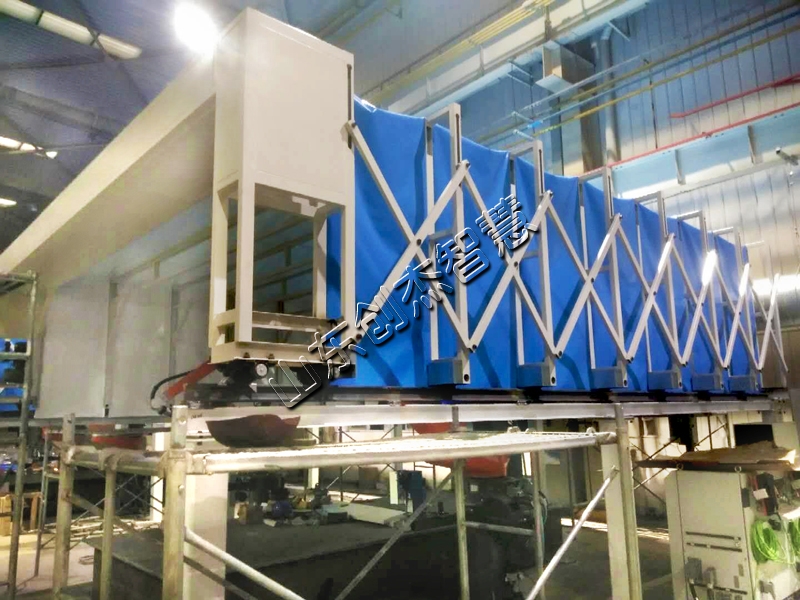

按照國家相關(guān)廢氣排放標(biāo)準(zhǔn)的規(guī)定,若要將有機(jī)廢氣凈化達(dá)標(biāo),需要由3臺(tái)蓄熱室組成的大型RTO進(jìn)行凈化。本項(xiàng)目采用的三室RTO是在兩室的基礎(chǔ)上增加了1臺(tái)吹掃用蓄熱室,如圖1所示。

According to the relevant national exhaust emission standards, in order to purify organic waste gas to meet the standards, a large RTO consisting of three heat storage chambers is required for purification. The three chamber RTO used in this project is an addition of one blowing heat storage chamber on the basis of two chambers, as shown in Figure 1.

RTO正常運(yùn)行時(shí),廢氣的進(jìn)氣和排氣通過閥門切換來完成。第1個(gè)工作周期中,廢氣自下而上經(jīng)A蓄熱室升溫,然后進(jìn)入燃燒室氧化放熱;氧化放熱結(jié)束后,自上而下通過B蓄熱室,與蓄熱室內(nèi)的填料進(jìn)行換熱,將熱量傳遞給B蓄熱室,再經(jīng)過工藝管路進(jìn)入煙囪排放;此時(shí)C蓄熱室處于吹掃狀態(tài),用吹掃風(fēng)機(jī)將蓄熱室(含集氣室)中的滯留廢氣吹入燃燒室氧化處理,防止因蓄熱室的切換過程影響廢氣處理效率。第2個(gè)工作周期中,A蓄熱室處于吹掃狀態(tài),廢氣自下而上進(jìn)入B蓄熱室,與已吸收熱量的填料進(jìn)行換熱后,進(jìn)入燃燒室氧化放熱,再自上而下通過C蓄熱室,并將熱量傳遞給C蓄熱室后,進(jìn)入煙囪。第3個(gè)工作周期中,B蓄熱室處于吹掃狀態(tài),廢氣由C蓄熱室進(jìn)入,氧化放熱后,通過A蓄熱室進(jìn)入煙囪,完成了RTO裝置運(yùn)行的1個(gè)大周期,如此交替運(yùn)行。當(dāng)煙煤在隔絕空氣條件下加熱到950~1050℃,經(jīng)過干燥、熱解干餾、熔融、黏結(jié)、固化、收縮等階段,最終得到焦炭,這個(gè)過程稱為煉焦。煉焦過程產(chǎn)生的荒煤氣經(jīng)過回收和精制可以得到多種芳香烴和雜環(huán)化合物等基本化學(xué)原料,同時(shí)產(chǎn)生的焦?fàn)t煤氣是高熱值燃料,可以用來發(fā)電或供應(yīng)城市煤氣。因此,本項(xiàng)目以能源高效利用為目的,采用焦?fàn)t煤氣代替輔助燃料,可以節(jié)約成本,提高焦?fàn)t煤氣利用率,同時(shí)能夠滿足RTO裝置正常運(yùn)行時(shí)的燃料需求。該裝置主要由燃燒室、蓄熱室(含集氣室)及切換閥門組成。

During normal operation of RTO, the intake and exhaust of exhaust gases are achieved through valve switching. In the first working cycle, the exhaust gas is heated from bottom to top through the A heat storage chamber, and then enters the combustion chamber for oxidation and heat release; After the oxidation heat release is completed, it passes through the B heat storage chamber from top to bottom, exchanges heat with the packing in the heat storage chamber, transfers the heat to the B heat storage chamber, and then enters the chimney through the process pipeline for discharge; At this time, the C heat storage chamber is in a blowing state. Use a blowing fan to blow the residual exhaust gas in the heat storage chamber (including the gas collection chamber) into the combustion chamber for oxidation treatment, to prevent the switching process of the heat storage chamber from affecting the efficiency of exhaust gas treatment. In the second working cycle, the A heat storage chamber is in a purging state, and the exhaust gas enters the B heat storage chamber from bottom to top. After exchanging heat with the heat absorbed packing, it enters the combustion chamber for oxidation and heat release, and then passes through the C heat storage chamber from top to bottom, transferring the heat to the C heat storage chamber before entering the chimney. In the third working cycle, the B heat storage chamber is in a purging state, and the exhaust gas enters from the C heat storage chamber. After oxidation and heat release, it enters the chimney through the A heat storage chamber, completing one major cycle of RTO device operation, and so on alternate operation. When bituminous coal is heated to 950-1050 ℃ under isolated air conditions, it undergoes stages such as drying, pyrolysis, melting, bonding, solidification, and shrinkage to finally obtain coke, which is called coking. The raw gas generated during the coking process can be recovered and refined to obtain various basic chemical raw materials such as aromatic hydrocarbons and heterocyclic compounds. At the same time, the coke oven gas produced is a high calorific value fuel that can be used for power generation or supplying urban gas. Therefore, this project aims to achieve efficient energy utilization by using coke oven gas instead of auxiliary fuel, which can save costs, improve the utilization rate of coke oven gas, and meet the fuel demand during the normal operation of RTO equipment. The device mainly consists of a combustion chamber, a heat storage chamber (including a gas collection chamber), and a switching valve.

焦化廢氣處理工藝流程

Coking waste gas treatment process flow

從化產(chǎn)區(qū)域各排氣洗凈塔后收集的廢氣進(jìn)入廢氣總管,經(jīng)過安全水封、捕霧器后進(jìn)入緩沖罐,由廢氣引風(fēng)機(jī)輸送,經(jīng)過阻火器后進(jìn)入RTO進(jìn)行焚燒。

The exhaust gas collected from various exhaust cleaning towers in the chemical production area enters the exhaust gas main pipe, passes through the safety water seal and mist trap, enters the buffer tank, is transported by the exhaust induced draft fan, passes through the flame arrester, and enters the RTO for incineration.

本項(xiàng)目中RTO收集處理的廢氣有14路,各排氣洗凈塔洗滌后的廢氣通過各自的調(diào)節(jié)閥控制排出壓力,保證廢氣進(jìn)入廢氣總管。RTO冷態(tài)啟動(dòng)后,首先啟動(dòng)吹掃風(fēng)機(jī),用新鮮空氣對(duì)設(shè)備進(jìn)行吹掃;吹掃結(jié)束后,燃燒系統(tǒng)進(jìn)行燃?xì)鈾z漏,確保點(diǎn)火系統(tǒng)安全;檢漏完成后,啟動(dòng)燃燒器,通過9個(gè)閥門的周期切換完成3個(gè)填料床的預(yù)熱;預(yù)熱結(jié)束后焦化廢氣進(jìn)入RTO進(jìn)行焚燒,燃燒室溫度開始緩慢提升。如果燃燒室溫度持續(xù)上升,說明廢氣濃度過高,當(dāng)溫度達(dá)到1100℃時(shí),打開高溫排放閥,將多余的熱量直接排放至煙囪;當(dāng)溫度達(dá)到1180℃時(shí),系統(tǒng)自動(dòng)報(bào)警;當(dāng)溫度達(dá)到1200℃時(shí),為了確保RTO裝置安全,RTO開啟自動(dòng)離線程序。

In this project, there are 14 exhaust gases collected and processed by RTO. The exhaust gases after washing in each exhaust cleaning tower are controlled by their respective regulating valves to ensure that the exhaust gases enter the exhaust manifold. After RTO cold start, first start the blowing fan and blow the equipment with fresh air; After the purge is completed, the combustion system conducts gas leak detection to ensure the safety of the ignition system; After the leak detection is completed, start the burner and complete the preheating of 3 packing beds through the periodic switching of 9 valves; After preheating, the coking exhaust gas enters the RTO for incineration, and the combustion chamber temperature begins to slowly increase. If the temperature of the combustion chamber continues to rise, it indicates that the concentration of exhaust gas is too high. When the temperature reaches 1100 ℃, open the high-temperature discharge valve and directly discharge the excess heat into the chimney; When the temperature reaches 1180 ℃, the system will automatically sound an alarm; When the temperature reaches 1200 ℃, in order to ensure the safety of the RTO device, the RTO starts the automatic offline program.

RTO離線時(shí),燃燒系統(tǒng)熄火,廢氣風(fēng)機(jī)減速直至停機(jī),新風(fēng)閥打開,引入小風(fēng)量新鮮空氣進(jìn)入RTO蓄熱室,開始RTO降溫程序。為了降低高溫閥的溫度,在高溫閥設(shè)置了1套水冷系統(tǒng),以確保高溫閥的密封性能,水冷系統(tǒng)由軟水槽、軟水循環(huán)泵及軟水冷卻器組成,軟水通過浮球液位計(jì)自動(dòng)補(bǔ)充到軟水槽中,通過軟水循環(huán)泵輸送至高溫閥,再通過軟水冷卻器被循環(huán)水冷卻后回到軟水槽。

When the RTO is offline, the combustion system stalls, the exhaust fan slows down until it stops, the fresh air valve opens, and a small amount of fresh air is introduced into the RTO heat storage chamber to start the RTO cooling program. In order to reduce the temperature of the high-temperature valve, a water cooling system is installed in the high-temperature valve to ensure its sealing performance. The water cooling system consists of a soft water tank, a soft water circulation pump, and a soft water cooler. Soft water is automatically replenished to the soft water tank through a float level gauge, transported to the high-temperature valve through the soft water circulation pump, and then cooled by the circulating water through the soft water cooler before returning to the soft water tank.

由于焦化廢氣中有機(jī)成分的沸點(diǎn)較高,易凝結(jié)在蓄熱填料底部,堵塞填料床層,本項(xiàng)目中RTO設(shè)置了1套反燒程序,當(dāng)床層底部和頂部的壓差達(dá)到3kPa時(shí),自動(dòng)啟動(dòng)反燒程序,將凝結(jié)在蓄熱填料底部的膠狀物質(zhì)氧化,從而達(dá)到對(duì)蓄熱床層清理的目的。反燒程序與正常運(yùn)行一樣,只不過是排氣溫度達(dá)到480℃時(shí)再進(jìn)行閥門切換。3個(gè)床層底部溫度依次達(dá)到480℃時(shí),反燒程序自動(dòng)結(jié)束,反燒程序有自動(dòng)和手動(dòng)2種方式。手動(dòng)方式可根據(jù)實(shí)際運(yùn)行情況,點(diǎn)擊反燒按鈕進(jìn)行清理。

Due to the high boiling point of organic components in coking waste gas, they are prone to condense at the bottom of the thermal storage packing and block the packing bed. In this project, RTO has set up a set of reverse heating program. When the pressure difference between the bottom and top of the bed reaches 3kPa, the reverse heating program will automatically start to oxidize the gel like substances condensed at the bottom of the thermal storage packing, thereby achieving the purpose of cleaning the thermal storage bed. The anti burn program runs normally, except that the valve is switched when the exhaust temperature reaches 480 ℃. When the temperature at the bottom of the three beds reaches 480 ℃ in sequence, the reverse heating program will automatically end. The reverse heating program has two modes: automatic and manual. The manual mode can be cleaned by clicking the anti burn button according to the actual operating situation.

為了保證系統(tǒng)安全,風(fēng)機(jī)前設(shè)置了3套可燃?xì)怏w濃度監(jiān)測儀,其中1套為快速反應(yīng)型,響應(yīng)時(shí)間小于1s,用于快速連鎖,當(dāng)廢氣中可燃組分濃度達(dá)到爆炸下限的25%時(shí),系統(tǒng)自動(dòng)連鎖停機(jī)。同時(shí)RTO設(shè)置了2個(gè)防爆門,當(dāng)爐內(nèi)壓力達(dá)到11kPa時(shí)自動(dòng)泄壓。

In order to ensure system safety, three sets of combustible gas concentration monitoring devices are installed in front of the fan, one of which is a rapid response type with a response time of less than 1 second, used for rapid interlocking. When the concentration of combustible components in the exhaust gas reaches 25% of the lower explosive limit, the system automatically interlocks and shuts down. At the same time, RTO is equipped with two explosion-proof doors, which automatically release pressure when the furnace pressure reaches 11kPa.

RTO裝置工藝優(yōu)化及運(yùn)行結(jié)果分析

Process optimization and operation result analysis of RTO device

采用RTO裝置處理焦化廢氣,優(yōu)化RTO裝置的工藝性能對(duì)提高有機(jī)廢氣處理效率,實(shí)現(xiàn)廢氣達(dá)標(biāo)排放至關(guān)重要,本項(xiàng)目在RTO工藝設(shè)計(jì)等方面做了升級(jí)和改進(jìn)。

The use of RTO equipment to treat coking waste gas and optimize the process performance of RTO equipment are crucial for improving the efficiency of organic waste gas treatment and achieving standard emissions of waste gas. This project has upgraded and improved the RTO process design and other aspects.

1)采用焦?fàn)t煤氣作為輔助燃料

1) Using coke oven gas as auxiliary fuel

本項(xiàng)目采用焦?fàn)t煤氣作為輔助燃料,既節(jié)約了成本,又提高了焦?fàn)t煤氣的利用率。從用戶記錄所得到的輔助燃料使用量表明,RTO裝置冷啟動(dòng)時(shí)所需焦?fàn)t煤氣為240m3/h,能夠滿足RTO裝置正常運(yùn)行時(shí)的燃料需求。

This project uses coke oven gas as an auxiliary fuel, which not only saves costs but also improves the utilization rate of coke oven gas. The auxiliary fuel usage obtained from user records indicates that the required coke oven gas for cold start of the RTO device is 240m3/h, which can meet the fuel demand for normal operation of the RTO device.

2)RTO前端增加安全水封、捕霧器和阻火器水封的主要作用是防止高溫回火。

2) The main purpose of adding safety water seals, fog traps, and flame arresters to the RTO front-end is to prevent high-temperature tempering.

由于其安全性能好,可用在管道收集前端防止回火;焦化廢氣中含有少量的水分,為使進(jìn)入RTO內(nèi)部的焦化廢氣更加潔凈,增加了捕霧器用于氣液分離;與此同時(shí),由于廢氣中含有易燃?xì)怏w,為了阻止易燃?xì)怏w在RTO內(nèi)燃燒時(shí)火焰?zhèn)鞑サ秸麄€(gè)管網(wǎng)中,在RTO進(jìn)氣管道前端增加了阻火器。

Due to its good safety performance, it can be used at the front end of pipeline collection to prevent backfire; Coking waste gas contains a small amount of moisture. In order to make the coking waste gas entering the RTO cleaner, a mist trap is added for gas-liquid separation; At the same time, due to the presence of flammable gases in the exhaust gas, a flame arrester has been added at the front end of the RTO intake pipeline to prevent the spread of flames throughout the entire pipeline when flammable gases burn inside the RTO.

3)高溫閥水冷系統(tǒng)

3) High temperature valve water cooling system

在大多數(shù)的RTO裝置中,高溫閥主要靠自然散熱。考慮到發(fā)生緊急情況時(shí)燃燒室的溫度過高,本項(xiàng)目采用循環(huán)水冷卻系統(tǒng)。水冷系統(tǒng)由軟水槽、軟水循環(huán)泵及軟水冷卻器組成,軟水通過浮球液位計(jì)自動(dòng)補(bǔ)充到軟水槽中,通過軟水循環(huán)泵輸送至高溫閥,再通過軟水冷卻器被循環(huán)水冷卻后進(jìn)入軟水槽。

In most RTO devices, high-temperature valves mainly rely on natural heat dissipation. Considering the high temperature of the combustion chamber in case of emergency, this project adopts a circulating water cooling system. The water cooling system consists of a soft water tank, a soft water circulation pump, and a soft water cooler. Soft water is automatically replenished to the soft water tank through a float level gauge, transported to the high-temperature valve through the soft water circulation pump, and then cooled by circulating water through the soft water cooler before entering the soft water tank.

總結(jié)

summary

經(jīng)工藝優(yōu)化后的RTO裝置運(yùn)行結(jié)果分析表明:

The analysis of the operation results of the RTO device after process optimization shows that:

1)通過多次抽樣測量,RTO燃燒室表面溫度基本維持在50~70℃,滿足最高溫度≤75℃的設(shè)計(jì)要求。

1) Through multiple sampling measurements, the surface temperature of the RTO combustion chamber is maintained at 50-70 ℃, meeting the design requirement of a maximum temperature of ≤ 75 ℃.

2)燃燒室溫度始終維持在850~1100℃,保證了有機(jī)廢氣中的有機(jī)成分充分氧化燃燒。

2) The combustion chamber temperature is always maintained at 850-1100 ℃, ensuring that the organic components in the organic exhaust gas are fully oxidized and burned.

3)煙囪平均出口溫度120℃,低于150℃的設(shè)計(jì)要求。

3) The average outlet temperature of the chimney is 120 ℃, which is lower than the design requirement of 150 ℃.

4)經(jīng)當(dāng)?shù)丨h(huán)保部門多次抽查,經(jīng)過RTO裝置處理的焦化廢氣達(dá)到GB16171—2012《煉焦化學(xué)工業(yè)污染物排放標(biāo)準(zhǔn)》的要求,有機(jī)廢氣的凈化率達(dá)到了99%,CO的凈化率達(dá)到了97%。

4) After multiple spot checks by the local environmental protection department, the coking waste gas treated by the RTO device meets the requirements of GB16171-2012 "Emission Standards for Pollutants in Coking Chemical Industry", with a purification rate of 99% for organic waste gas and 97% for CO.

本文由 RTO廢氣處理設(shè)備 友情奉獻(xiàn).更多有關(guān)的知識(shí)請(qǐng)點(diǎn)擊 http://www.9qmv.com/ 真誠的態(tài)度.為您提供為全面的服務(wù).更多有關(guān)的知識(shí)我們將會(huì)陸續(xù)向大家奉獻(xiàn).敬請(qǐng)期待.

This article is a friendly contribution from RTO waste gas treatment equipment For more related knowledge, please click http://www.9qmv.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

上一篇:自動(dòng)式拋丸機(jī):不銹鋼噴砂與拋丸區(qū)別對(duì)比

下一篇:工業(yè)涂裝流水線的操作說明

魯公網(wǎng)安備 37142502000144號(hào)

魯公網(wǎng)安備 37142502000144號(hào)