移動伸縮式噴漆房的結構組成和工作原理

以下是關于移動伸縮噴漆房的說明介紹:

The following is an introduction to the mobile telescopic paint booth:

結構組成

structural composition

- 移動框架室體:整體為鋼制框架結構,每組框架間有阻燃PVC布密封連接,可前后伸縮移動,帶動蓬布展開合攏。?

-Mobile frame chamber: The overall structure is a steel frame structure, with flame-retardant PVC cloth sealed connections between each group of frames, which can be extended and retracted forward and backward, driving the canopy to unfold and close.?

- 傳動機構:移動行走機構參照龍門吊車裝置設計,主驅動裝置一般一邊設2個,前后布置,通過減速機與鏈條傳動驅動鏈輪行走,采用雙主動輪,兩邊分別驅動、互相連鎖,保障房體沿軌道平穩(wěn)移動。

-Transmission mechanism: The mobile walking mechanism is designed with reference to the gantry crane device. The main driving device is generally set up with 2 on each side, arranged in front and behind. The sprocket is driven by a reducer and a chain to move, using dual active wheels that drive and interlock with each other on both sides to ensure smooth movement of the building along the track.

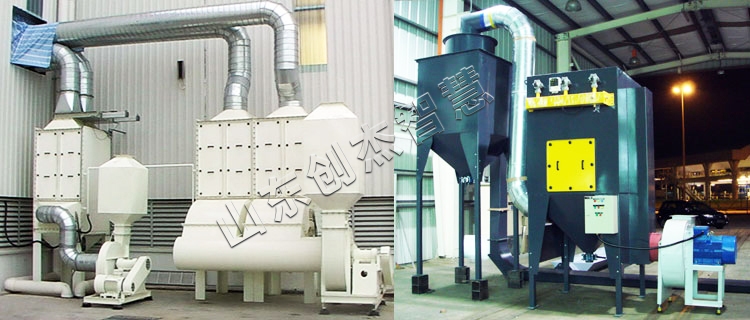

- 送排風系統(tǒng):送風量不變,將大功率風機變?yōu)槿舾尚★L機,直接從車間抽風過濾后向噴漆室靜壓層送風,送排風系統(tǒng)通常布置在室體端部,部分大型設備送風放置在室體頂部隨室體移動。

-Air supply and exhaust system: The air supply volume remains unchanged. The high-power fan is converted into several small fans, which directly extract and filter air from the workshop and supply it to the static pressure layer of the paint spraying room. The air supply and exhaust system is usually arranged at the end of the room, and some large equipment air supply is placed at the top of the room and moves with the room.

- 照明系統(tǒng):工作區(qū)內安裝防爆照明燈,滿足生產(chǎn)照明需要,確保室內照明度。

-Lighting system: Install explosion-proof lighting fixtures in the work area to meet production lighting needs and ensure indoor illumination.

- 漆霧廢氣處理系統(tǒng):可根據(jù)客戶需求選擇濕式、干式或二者同時使用的處理方式,如水簾噴漆房、無泵水幕噴漆室、干式噴漆房等,以處理噴漆過程中產(chǎn)生的漆霧和廢氣。

-Paint mist and exhaust gas treatment system: Wet, dry, or a combination of both treatment methods can be selected according to customer needs, such as water curtain painting rooms, pumpless water curtain painting rooms, dry painting rooms, etc., to treat the paint mist and exhaust gas generated during the painting process.

- 電控系統(tǒng):包括防爆電控箱等,集中控制伸縮噴漆房內所有電器部分,實現(xiàn)對房體伸縮、照明、送排風等功能的控制,可實現(xiàn)遙控和手動自由切換。

-Electrical control system: including explosion-proof electrical control box, etc., which centrally controls all electrical parts in the telescopic spray painting room, realizing the control of functions such as room expansion, lighting, air supply and exhaust, and can be freely switched between remote control and manual operation.

工作原理

working principle

移動室收縮合攏時,將工件移入工作區(qū),展開時可進行工件的噴漆或打磨等工作。工作流程為:伸縮前室收縮合攏→工件移動就位→伸縮前室展開罩住工件→工件噴漆(打磨/刮膩子)→伸縮前室收縮合攏→工件移出工作場地。

When the mobile chamber shrinks and closes, the workpiece is moved into the work area, and when unfolded, painting or polishing of the workpiece can be carried out. The workflow is as follows: shrink and close the telescopic chamber → move the workpiece into position → unfold and cover the workpiece with the telescopic chamber → spray paint the workpiece (polish/scrape putty) → shrink and close the telescopic chamber → remove the workpiece from the work site.

特點及優(yōu)勢

Feature and advantage

- 空間利用高效:可根據(jù)產(chǎn)量大小任意調整噴漆區(qū),不噴漆時可將前室收攏,騰出空間用于其他交叉作業(yè)工序,提高車間空間利用率。

-Efficient space utilization: The painting area can be adjusted according to the production volume. When not painting, the front compartment can be folded up to free up space for other cross operation processes, improving the utilization rate of workshop space.

- 操作簡便安全:采用兩邊分別驅動、互相連鎖的方式運行,前后安全限位控制,機械運行穩(wěn)定。配備運行報警燈、雙減速機互鎖、雙重限位開關、自動誤差消除、防打滑裝置及掃軌鏟等,保障操作安全。

-Easy and safe operation: It operates in a dual drive and interlocking manner, with front and rear safety limit control, ensuring stable mechanical operation. Equipped with operation alarm lights, dual gearbox interlocks, dual limit switches, automatic error elimination, anti-skid devices, and rail sweeping shovels to ensure operational safety.

- 適用范圍廣泛:適用于大中型、天車吊運的工件,也可用于小型工件集中噴漆,還能用于大型焊接工件的焊接作業(yè)等。

-Widely applicable: suitable for large and medium-sized workpieces lifted by overhead cranes, can also be used for centralized painting of small workpieces, and can also be used for welding operations of large welding workpieces.

- 定制化程度高:可根據(jù)客戶的實際生產(chǎn)需要定做各種型號的非標尺寸,還可選配加熱送風系統(tǒng)、輔助烘干房裝置及各種噴漆空氣凈化設備,滿足不同客戶的需求。

-High degree of customization: Various non-standard sizes can be customized according to the actual production needs of customers. Heating and air supply systems, auxiliary drying room devices, and various spray painting air purification equipment can also be selected to meet the needs of different customers.

本文由 伸縮式噴漆房 友情奉獻.更多有關的知識請點擊 http://www.9qmv.com/ 真誠的態(tài)度.為您提供為全面的服務.更多有關的知識我們將會陸續(xù)向大家奉獻.敬請期待.

This article is a friendly contribution from the retractable paint booth For more related knowledge, please click http://www.9qmv.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

上一篇:涂裝線:高效、環(huán)保與創(chuàng)新融合的噴粉線系統(tǒng)

下一篇:一文解析透徹噴砂房的結構組成和工作原理

魯公網(wǎng)安備 37142502000144號

魯公網(wǎng)安備 37142502000144號