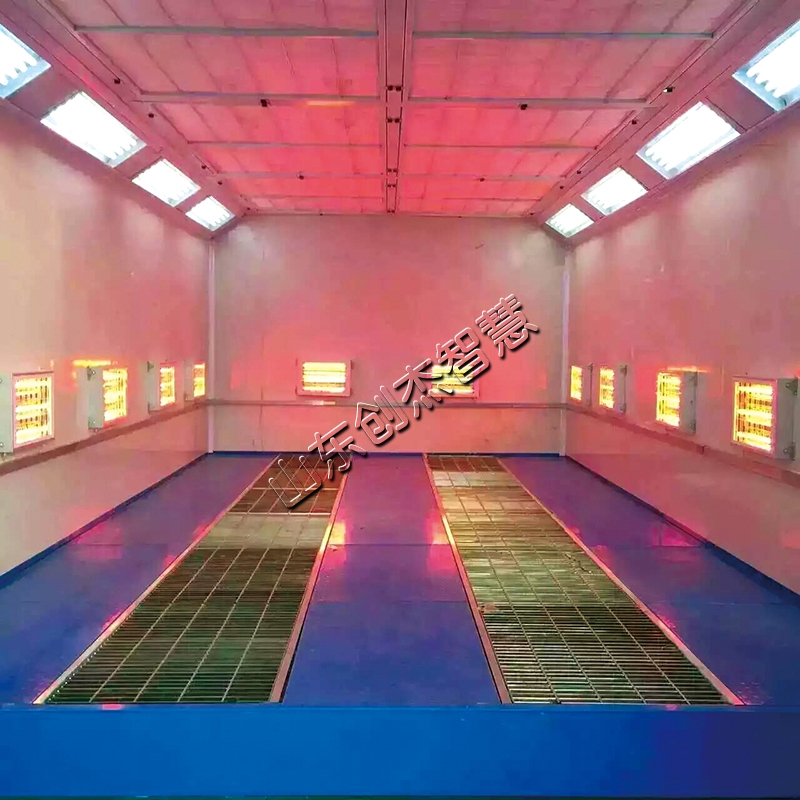

涂裝線:燃氣催化紅外加熱技術解決了傳統熱風烘道能耗高問題

涂裝線燃氣催化紅外加熱技術,解決了該企業長期的傳統熱風烘道能耗高、固化慢、品質不穩定等難題,實現了生產效率與節能降耗的雙重突破,為電車電池制造領域樹立了綠色智造新標桿。

The gas catalytic infrared heating technology for the coating line has solved the long-standing problems of high energy consumption, slow curing, and unstable quality in the traditional hot air drying channel of the enterprise, achieving a dual breakthrough in production efficiency and energy conservation, and setting a new benchmark for green and intelligent manufacturing in the field of electric vehicle battery manufacturing.

據悉,傳統噴粉線多采用電加熱或傳統燃氣加熱方式,存在能耗高、預熱慢、溫度控制精度不足等問題。創杰能提供的燃氣催化紅外加熱系統,通過催化燃燒技術將燃氣轉化為高效紅外輻射能,熱效率提升40%以上,產線預熱時間縮短30%,同時實現±1℃的精準溫控,顯著提升了電池噴粉涂層的均勻性和附著力。經實測,該技術幫助企業單條產線年節約不少能源成本,碳排放量降低30%以上。

It is reported that traditional powder spraying lines often use electric heating or traditional gas heating methods, which have problems such as high energy consumption, slow preheating, and insufficient temperature control accuracy. The gas catalytic infrared heating system provided by Chuangjie Energy converts gas into efficient infrared radiation energy through catalytic combustion technology, increasing thermal efficiency by more than 40%, shortening production line preheating time by 30%, and achieving precise temperature control of ± 1 ℃, significantly improving the uniformity and adhesion of battery powder coating. Through actual testing, this technology has helped enterprises save a lot of energy costs and reduce carbon emissions by more than 30% per year for a single production line.

“此次合作不僅是設備的升級,更是新能源電池固化工藝的革命。”企業項目負責人表示,新技術解決了原有產線能耗高、維護頻繁的痛點,為后續擴產提供了可持續的解決方案。創杰能技術團隊還針對電池噴粉工藝特性,定制開發了智能溫控模塊,進一步優化了生產節拍。

This cooperation is not only an upgrade of equipment, but also a revolution in the solidification process of new energy batteries, "said the project leader of the enterprise. The new technology has solved the pain points of high energy consumption and frequent maintenance in the original production line, providing a sustainable solution for future expansion. The Chuangjie Energy technology team has also customized and developed an intelligent temperature control module based on the characteristics of battery powder coating technology, further optimizing the production cycle.

作為國內燃氣催化紅外領域的領軍企業,創杰能已在全國落地超200+工業節能改造案例。此次項目的成功交付,標志著該技術在新能源制造場景的成熟應用,為行業綠色轉型提供了可復制的技術范式。未來,雙方還將在制造業全流程節能領域展開深度合作。

As a leading enterprise in the field of gas catalytic infrared technology in China, Chuangjie Energy has implemented over 200 industrial energy-saving renovation cases nationwide. The successful delivery of this project marks the mature application of this technology in new energy manufacturing scenarios, providing a replicable technological paradigm for the industry's green transformation. In the future, both parties will also engage in in-depth cooperation in the field of energy conservation throughout the entire manufacturing process.

本文由 涂裝線 友情奉獻.更多有關的知識請點擊 http://www.9qmv.com/ 真誠的態度.為您提供為全面的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from the painting line For more related knowledge, please click http://www.9qmv.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

魯公網安備 37142502000144號

魯公網安備 37142502000144號