工業涂裝流水線:高效與優質的涂裝解決方案

工業涂裝流水線通過將工件預處理、涂裝、干燥等工序整合為連續生產系統,實現了涂裝過程的自動化與標準化,在汽車制造、機械加工、家電生產等領域發揮著核心作用。其優勢體現在生產效率、涂層質量、資源利用及環保控制等多個維度,成為現代工業中提升產品外觀與防護性能的關鍵設施。

The industrial painting assembly line integrates processes such as workpiece pretreatment, painting, and drying into a continuous production system, achieving automation and standardization of the painting process. It plays a core role in fields such as automotive manufacturing, mechanical processing, and home appliance production. Its advantages are reflected in multiple dimensions such as production efficiency, coating quality, resource utilization, and environmental control, making it a key facility for improving product appearance and protective performance in modern industry.

生產效率的提升是工業涂裝流水線最顯著的優勢,通過工序銜接與自動化操作減少時間浪費。傳統人工涂裝中,工件轉運、等待干燥等環節占用大量時間,而流水線將預處理(如除油、除銹、磷化)、底漆噴涂、面漆噴涂、固化干燥等工序按順序排列,工件通過懸掛鏈或傳送帶自動流轉,各工序無縫銜接,避免了工序間的閑置等待。自動化噴涂設備(如機械臂、往復式噴涂機)可根據工件形狀預設噴涂路徑,每秒可完成數次噴涂動作,效率是人工噴涂的 3-5 倍,且可 24 小時連續運行,大幅提升單日涂裝量。對于批量生產的工件(如汽車車身、家電外殼),流水線能實現標準化節拍生產,每小時可處理數十至上百件工件,滿足大規模生產的需求。

The improvement of production efficiency is the most significant advantage of industrial coating assembly lines, which reduces time waste through process linkage and automation operations. In traditional manual painting, the transportation of workpieces and waiting for drying take up a lot of time, while the assembly line arranges the pre-treatment (such as oil removal, rust removal, phosphating), primer spraying, topcoat spraying, curing and drying processes in sequence. The workpieces are automatically circulated through hanging chains or conveyor belts, and each process is seamlessly connected, avoiding idle waiting between processes. Automated spraying equipment (such as robotic arms and reciprocating spraying machines) can preset spraying paths according to the shape of the workpiece, complete multiple spraying actions per second, and have an efficiency 3-5 times that of manual spraying. They can also operate continuously for 24 hours, greatly increasing the daily coating volume. For mass-produced workpieces such as car bodies and home appliance casings, assembly lines can achieve standardized production pace, processing tens to hundreds of workpieces per hour to meet the needs of large-scale production.

涂層質量的穩定性與一致性是流水線相比人工涂裝的核心競爭力,通過精準控制確保涂層性能達標。流水線配備的噴涂設備能精確控制涂料用量、噴涂壓力、霧化效果,確保涂層厚度均勻(偏差可控制在 ±5 微米內),避免人工噴涂常見的流掛、漏噴、厚度不均等問題。預處理工序采用自動化噴淋或浸浴方式,工件表面處理更徹底,油污、銹跡去除率高,為涂層附著提供良好基礎,減少后期涂層脫落風險。干燥固化環節通過恒溫烘箱或紅外加熱系統,精確控制溫度與時間(如面漆固化溫度控制在 120-180℃,誤差不超過 ±2℃),確保涂層充分固化,提升硬度、耐腐蝕性等性能。這種標準化生產使同批次工件的涂層外觀(如光澤度、顏色)和性能高度一致,滿足高端產品的質量要求。

The stability and consistency of coating quality are the core competitiveness of assembly line compared to manual coating, ensuring that coating performance meets standards through precise control. The spraying equipment equipped on the assembly line can accurately control the amount of coating, spraying pressure, and atomization effect, ensuring uniform coating thickness (deviation can be controlled within ± 5 microns), avoiding common problems such as sagging, missed spraying, and uneven thickness in manual spraying. The pre-treatment process adopts automated spraying or immersion methods, which result in more thorough surface treatment of the workpiece, high removal rate of oil stains and rust, providing a good foundation for coating adhesion and reducing the risk of coating detachment in the later stage. The drying and curing process uses a constant temperature oven or infrared heating system to precisely control the temperature and time (such as controlling the curing temperature of the topcoat at 120-180 ℃ with an error not exceeding ± 2 ℃), ensuring that the coating is fully cured and improving its hardness, corrosion resistance, and other properties. This standardized production ensures that the coating appearance (such as glossiness, color) and performance of the same batch of workpieces are highly consistent, meeting the quality requirements of high-end products.

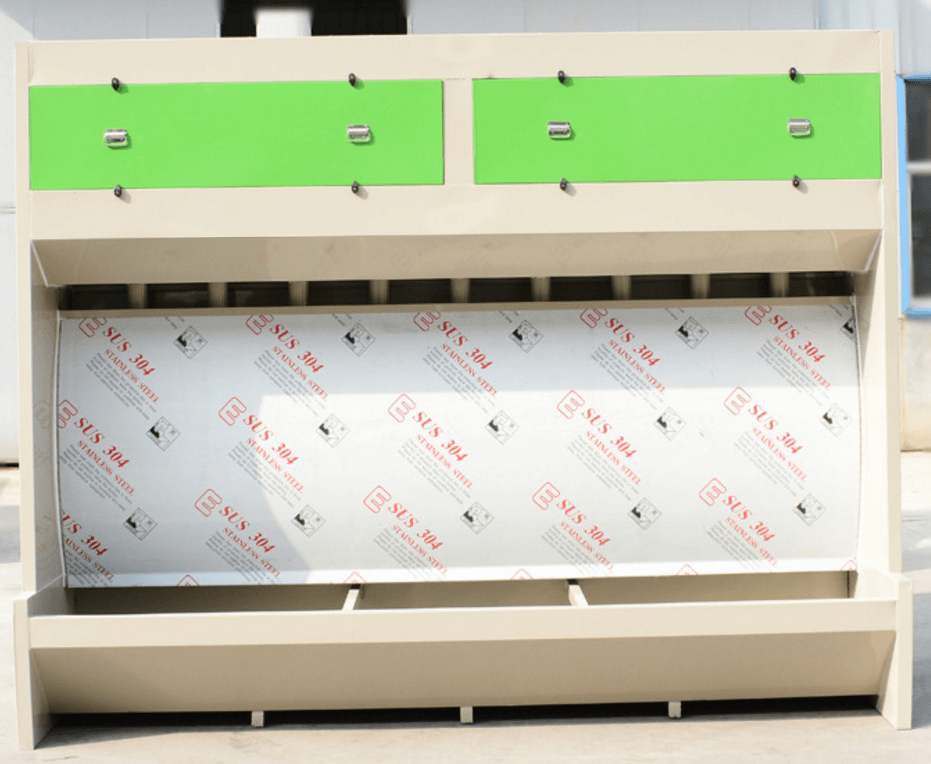

資源利用率的提高降低了生產成本,體現在涂料與能源的節約上。自動化噴涂設備通過靜電噴涂技術使涂料粒子帶電,吸附在工件表面,涂料利用率可達 80%-90%,遠高于人工噴涂的 30%-50%,大幅減少涂料浪費。多余的涂料通過回收系統(如水簾柜、粉末回收裝置)收集后可重新利用,進一步降低原料消耗。能源利用方面,流水線的干燥系統采用余熱回收裝置,將排放的熱氣中的熱量回收用于預熱新風,節能率達 20%-30%;部分流水線采用變頻技術,根據工件數量調節設備運行功率,避免空載能耗。對于高價值涂料(如防腐蝕涂料、耐高溫涂料),這種資源節約帶來的成本降低更為顯著。

The improvement of resource utilization has reduced production costs, reflected in the savings of coatings and energy. Automated spraying equipment uses electrostatic spraying technology to charge coating particles and adsorb them onto the surface of the workpiece. The coating utilization rate can reach 80% -90%, which is much higher than the 30% -50% of manual spraying, greatly reducing coating waste. Excess paint can be collected and reused through recycling systems such as water curtain cabinets and powder recycling devices, further reducing raw material consumption. In terms of energy utilization, the drying system of the assembly line adopts a waste heat recovery device to recover the heat from the emitted hot gas for preheating fresh air, with an energy-saving rate of 20% -30%; Part of the assembly line adopts frequency conversion technology to adjust the operating power of the equipment according to the number of workpieces, avoiding no-load energy consumption. For high-value coatings such as anti-corrosion coatings and high-temperature resistant coatings, the cost reduction brought by resource conservation is more significant.

環保性能的強化適應了現代工業的綠色發展需求,減少涂裝過程的污染物排放。流水線配備的廢氣處理系統(如活性炭吸附、催化燃燒裝置)可過濾噴涂產生的揮發性有機物(VOCs),處理效率達 90% 以上,使廢氣排放符合環保標準。廢水處理系統對預處理環節產生的含油、含磷廢水進行凈化處理,去除率高,處理后的水可循環用于預處理工序,實現水資源循環利用。部分流水線采用粉末涂料或水性涂料,從源頭減少有機溶劑的使用,降低 VOCs 排放。此外,自動化操作減少了人工與涂料的直接接觸,通過封閉噴涂室與通風系統,改善作業環境,保護操作人員健康。

The strengthening of environmental performance meets the green development needs of modern industry and reduces pollutant emissions during the coating process. The exhaust gas treatment system equipped on the assembly line, such as activated carbon adsorption and catalytic combustion devices, can filter volatile organic compounds (VOCs) generated by spraying, with a treatment efficiency of over 90%, ensuring that exhaust emissions meet environmental standards. The wastewater treatment system purifies the oily and phosphorus containing wastewater generated in the pretreatment process, with a high removal rate. The treated water can be recycled for the pretreatment process, achieving water resource recycling. Some assembly lines use powder coatings or water-based coatings to reduce the use of organic solvents from the source and lower VOCs emissions. In addition, automated operations reduce direct contact between manual labor and paint, improve the working environment, and protect the health of operators through enclosed spraying rooms and ventilation systems.

本文由工業涂裝流水線友情奉獻.更多有關的知識請點擊:http://www.9qmv.com我們將會對您提出的疑問進行詳細的解答,歡迎您登錄網站留言.

This article is dedicated to the automatic shot blasting machine and friendship For more information, please click: http://www.9qmv.com We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

上一篇:自動噴砂房的核心原理及主要用途

下一篇:多工位焊煙除塵設備全方位解析

魯公網安備 37142502000144號

魯公網安備 37142502000144號