車(chē)間整體除塵設(shè)備:智能鋼構(gòu)車(chē)間焊煙除塵方案助力企業(yè)解決煙塵難題

01項(xiàng)目概況

01 Project Overview

本方案主要針對(duì)焊接車(chē)間的人工焊接等工位。經(jīng)我司現(xiàn)場(chǎng)勘測(cè)并和甲方相關(guān)人員溝通得知,生產(chǎn)車(chē)間除塵方案主要為手工焊接區(qū)域,共有57個(gè)工位,具體布局如上圖所示:

This plan is mainly aimed at manual welding and other workstations in the welding workshop. According to our on-site survey and communication with relevant personnel from Party A, the dust removal plan for the production workshop mainly involves manual welding areas, with a total of 57 workstations. The specific layout is shown in the above figure:

為保護(hù)工人的身體健康,改善焊接車(chē)間內(nèi)的空氣質(zhì)量和作業(yè)環(huán)境,滿足國(guó)家職業(yè)衛(wèi)生和環(huán)境等相關(guān)標(biāo)準(zhǔn)的規(guī)定要求,決定對(duì)車(chē)間內(nèi)的焊接工位焊接時(shí)產(chǎn)生的煙塵進(jìn)行治理。我公司以用戶(hù)需求為依據(jù),以滿足生產(chǎn)工藝要求為設(shè)計(jì)原則,主要從焊接時(shí)的作業(yè)環(huán)境,大氣的排放標(biāo)準(zhǔn),設(shè)備的運(yùn)行可靠,操作維護(hù)便利等多方面的綜合考慮,力爭(zhēng)本除塵系統(tǒng)的結(jié)構(gòu)設(shè)計(jì)、設(shè)備造型及工裝配套設(shè)施等方面達(dá)到國(guó)內(nèi)外同類(lèi)產(chǎn)品的最先進(jìn)水平,將竭盡全力為貴公司提供最優(yōu)秀、最經(jīng)濟(jì)的煙塵治理方案。

In order to protect the physical health of workers, improve the air quality and working environment in the welding workshop, and meet the requirements of national occupational health and environmental standards, it has been decided to control the smoke and dust generated during welding at the welding stations in the workshop. Our company takes user needs as the basis and meets production process requirements as the design principle. We mainly consider various aspects such as the working environment during welding, atmospheric emission standards, reliable equipment operation, and convenient operation and maintenance. We strive to achieve the most advanced level of similar products at home and abroad in terms of the structural design, equipment modeling, and supporting facilities of this dust removal system. We will do our best to provide your company with the best and most economical smoke control solution.

由于環(huán)保標(biāo)準(zhǔn)不斷提高,為保證新增環(huán)保設(shè)備能滿足以后的標(biāo)準(zhǔn)升級(jí)要求,煙塵 經(jīng)過(guò)凈化后,排放濃度低于《大氣污染物綜合排放標(biāo)準(zhǔn)》(GB16297-1996)中Ⅱ類(lèi)地區(qū)大氣污染物項(xiàng)目排放限值中顆粒物濃度 120mg/m?標(biāo)準(zhǔn)要求,顆粒物排放濃度應(yīng)<20mg/m?。

Due to the continuous improvement of environmental standards, in order to ensure that the newly added environmental protection equipment can meet the requirements of future standard upgrades, after purification, the emission concentration of smoke and dust is lower than the particle concentration of 120mg/m in the emission limit of Class II air pollutant projects in the Comprehensive Emission Standards for Air Pollutants (GB16297-1996)? The standard requires that the concentration of particulate matter emissions should be less than 20mg/m?.

室內(nèi)噪聲衛(wèi)生標(biāo)準(zhǔn)設(shè)備及室內(nèi)系統(tǒng)噪音低于《工作場(chǎng)所有害因素職業(yè)接觸限制_物理有害因素》 (GBZ2.2-2007)中規(guī)定噪音職業(yè)接觸 85dB 的標(biāo)準(zhǔn)要求,在無(wú)其他外部噪音時(shí)應(yīng)<85dB。室內(nèi)空氣衛(wèi)生標(biāo)準(zhǔn)經(jīng)過(guò)治理后的車(chē)間粉塵濃度符合《工作場(chǎng)所有害因素職業(yè)接觸限制_化學(xué)有害 因素》(GBZ2.1-2019),車(chē)間電焊煙塵濃度<4mg/m?。驗(yàn)收標(biāo)準(zhǔn)以當(dāng)?shù)丨h(huán)保部門(mén)認(rèn)可的具有檢測(cè)資質(zhì)的第三方檢測(cè)機(jī)構(gòu)出具的驗(yàn)收?qǐng)?bào)告為驗(yàn)收依據(jù)。

The indoor noise hygiene standard equipment and indoor system noise should be lower than the standard requirement of 85dB for occupational exposure to hazardous factors in the workplace - Physical Hazardous Factors (GBZ2.2-2007), and should be less than 85dB when there is no other external noise. The workshop dust concentration after treatment according to the indoor air hygiene standard meets the requirements of "Occupational Exposure Limits to Hazardous Factors in the Workplace - Chemical Hazardous Factors" (GBZ2.1-2019), and the concentration of welding fumes in the workshop is less than 4mg/m?. The acceptance criteria are based on the acceptance report issued by a third-party testing institution with testing qualifications recognized by the local environmental protection department.

?附:驗(yàn)收表內(nèi)容

Attachment: Content of Acceptance Form

02方案構(gòu)成

02 Scheme Composition

185kw焊煙凈化器

185kw welding smoke purifier

除塵器型式:濾筒式除塵器品牌:美天為華除塵器箱體壁厚:(滿足負(fù)壓5000pa強(qiáng)度使用30年壽命要求) ?4mm濾筒品牌:美天為華濾材規(guī)格:日本東麗聚酯纖維+ PTFE覆膜過(guò)濾總面積:600m?過(guò)濾風(fēng)速:<1m/min濾筒尺寸:325*1000mm單只過(guò)濾面積:20㎡濾筒數(shù)量:80個(gè)排放濃度:≤10mg/m?控制方式:PLC控制主要元器件品牌:西門(mén)子濾筒安裝方式:垂直吊裝電磁閥品牌:協(xié)昌清灰方式:壓縮空氣自動(dòng)脈沖反吹數(shù)量:1套

Dust collector type: filter cartridge dust collector brand: Meitianweihua dust collector box wall thickness: (meets the requirement of negative pressure 5000pa strength and 30-year service life)? 4mm filter cartridge brand: Meitian Weihua filter material specifications: Japanese Toray polyester fiber+PTFE membrane filtration total area: 600m? Filtration wind speed:<1m/min filter cartridge size: 325 * 1000mm single filtration area: 20 ㎡ filter cartridge quantity: 80, emission concentration: ≤ 10mg/m? Control Method: PLC Control Main Component Brand: Siemens Filter Cartridge Installation Method: Vertical Lifting Electromagnetic Valve Brand: Xiechang Dust Cleaning Method: Compressed Air Automatic Pulse Backblowing Quantity: 1 set

焊煙輸送管道室內(nèi)外收塵管道主管道采用鍍鋅鋼板加工制成,所有風(fēng)管均為圓形截面,確保最大工況時(shí)下不出現(xiàn)管道震動(dòng);管件間法蘭連接,冷鍍鋅螺栓固定;支管匯入主管角度沿順風(fēng)方向角度不大于45°,兩條主分管道不合流,各自獨(dú)立進(jìn)入除塵器和風(fēng)機(jī)儀表等系統(tǒng);接管處用法蘭連接墊片用三元乙丙橡膠(含支架支點(diǎn)處,用橡膠墊);室內(nèi)支管厚度:采用鍍鋅風(fēng)管,厚度不小于1-1.2mm(詳見(jiàn)清單),直徑400-1500mm,室內(nèi)噪聲小于50dB。

The main pipeline of the indoor and outdoor dust collection pipeline for welding smoke conveying is made of galvanized steel plate processing, and all air ducts have circular cross-sections to ensure that there is no pipeline vibration under maximum working conditions; Flange connection between pipe fittings, fixed with cold galvanized bolts; The angle of the branch pipe merging into the main pipe along the downwind direction shall not exceed 45 °. The two main branch pipes shall not merge and shall enter the dust collector and fan instrument system independently; The flange connection gasket at the takeover is made of EPDM rubber (including rubber pads at the support pivot); Indoor branch pipe thickness: Galvanized air ducts are used, with a thickness of not less than 1-1.2mm (see list for details), a diameter of 400-1500mm, and indoor noise less than 50dB.

安全要求(1)?項(xiàng)目安裝符合《建筑設(shè)計(jì)防火規(guī)范》、《工業(yè)企業(yè)噪聲控制設(shè)計(jì)規(guī)范》及《工業(yè)企業(yè)設(shè)計(jì)衛(wèi)生標(biāo)準(zhǔn)》等相關(guān)標(biāo)準(zhǔn);(2)?電器設(shè)備布置留有安全通道,檢修空間;(3)?所有外露的運(yùn)動(dòng)部件須設(shè)安全防護(hù)罩;(4)?高壓配電室及低壓控制室均符合通風(fēng)規(guī)范;(5)?按國(guó)家地震局規(guī)定的地區(qū)地震烈度設(shè)計(jì),安裝有防雷措施,滿足國(guó)家及行業(yè)相關(guān)標(biāo)準(zhǔn)的要求;(6)?設(shè)備、建(構(gòu))筑物、管道支架等與道路水平凈距符合規(guī)范;(7)?架空管線與建(構(gòu))筑物、道路水平凈距、垂直凈距、相互間水平凈距、相互間交叉的垂直凈距按規(guī)范設(shè)計(jì);(8)?地下管線與建(構(gòu))筑物、道路水平凈距、穿越道路的垂直凈距、相互間水平凈距、相互交叉的垂直凈距按規(guī)范設(shè)計(jì);(9)?在可能危及人身安全的地方應(yīng)設(shè)置防護(hù)罩、防護(hù)欄桿、檢修通道、作業(yè)平臺(tái)、登高梯設(shè)施,且安全性須符合國(guó)家相關(guān)標(biāo)準(zhǔn);(10)?設(shè)備運(yùn)行穩(wěn)定可靠,易于操作,管理維護(hù)方便,易損件容易購(gòu)置、更換;(11)?所有室外設(shè)備要有防雨措施,滿足設(shè)備安全運(yùn)行和使用壽命以及相關(guān)標(biāo)準(zhǔn)驗(yàn)收的要求;(12)?固定機(jī)組(室內(nèi)、室外)要有安全防護(hù)欄,達(dá)到國(guó)家標(biāo)準(zhǔn)要求;

Safety requirements (1)? The project installation complies with relevant standards such as the "Code for Fire Protection Design of Buildings", "Code for Design of Noise Control in Industrial Enterprises", and "Hygiene Standards for Design of Industrial Enterprises"; (2)? Electrical equipment should be arranged with safe passages and maintenance spaces; (3)? All exposed moving parts must be equipped with safety shields; (4)? The high voltage distribution room and low voltage control room both comply with ventilation regulations; (5)? According to the seismic intensity design specified by the National Seismological Bureau, lightning protection measures are installed to meet the requirements of relevant national and industry standards; (6)? The horizontal clearance distance between equipment, buildings (structures), pipeline supports, etc. and the road meets the specifications; (7)? The horizontal clearance distance, vertical clearance distance, horizontal clearance distance between overhead pipelines and buildings (structures), roads, and the vertical clearance distance between intersections shall be designed in accordance with the specifications; (8)? The horizontal clearance distance between underground pipelines and buildings (structures), roads, vertical clearance distance when crossing roads, horizontal clearance distance between each other, and vertical clearance distance when crossing each other shall be designed in accordance with the specifications; (9)? Protective covers, guardrails, maintenance channels, work platforms, and climbing facilities should be installed in places that may endanger personal safety, and safety must comply with relevant national standards; (10)? The equipment runs stably and reliably, is easy to operate, has convenient management and maintenance, and vulnerable parts are easy to purchase and replace; (11)? All outdoor equipment must have rainproof measures to meet the requirements of safe operation, service life, and relevant standard acceptance of the equipment; (12)? Fixed units (indoor and outdoor) should have safety guardrails that meet national standards;

可折疊集氣罩

Foldable gas collection hood

安裝效果

installation effect

系統(tǒng)設(shè)備防腐及顏色除塵器顏色:白色鍍鋅金屬管道顏色:原色風(fēng)管支架顏色:與車(chē)間鋼柱防腐和顏色一致電動(dòng)風(fēng)閥顏色:防護(hù)等級(jí):室內(nèi)IP54,室外IP68鍍鋅原色(風(fēng)量泄漏量<0.3%)風(fēng)機(jī)進(jìn)出口軟連接顏色:316L金屬波紋管碳鋼法蘭連接防腐要求:除銹 Sa2.5,底漆(環(huán)氧富鋅)兩遍,面漆(聚氨酯)兩遍,漆膜總厚度120μm。

System equipment anti-corrosion and color dust collector color: white galvanized metal pipeline color: original color air duct support color: consistent with workshop steel column anti-corrosion and color electric air valve color: protection level: indoor IP54, outdoor IP68 galvanized original color (air leakage<0.3%) fan inlet and outlet soft connection color: 316L metal corrugated pipe carbon steel flange connection anti-corrosion requirements: rust removal Sa2.5, two coats of primer (epoxy zinc rich), two coats of topcoat (polyurethane), total paint film thickness of 120 μ m.

03產(chǎn)品介紹

03 Product Introduction

除塵系統(tǒng)-除塵過(guò)濾單元

Dust removal system - Dust removal filtration unit

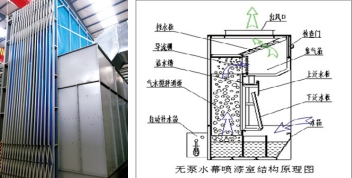

組成濾筒式除塵器的結(jié)構(gòu)是由進(jìn)風(fēng)管、排風(fēng)管、氣流分流分布板、除塵室、過(guò)濾濾筒單元、貯氣包、電磁脈沖閥、凈氣室、集灰斗等組成,類(lèi)似氣箱脈沖袋式除塵結(jié)構(gòu)。

The structure of a filter cartridge dust collector consists of an inlet duct, an exhaust duct, an airflow distribution plate, a dust removal chamber, a filter cartridge unit, an air storage bag, an electromagnetic pulse valve, a clean air chamber, an ash hopper, etc., similar to the pulse bag dust removal structure of an air box.

原理塵氣體在負(fù)壓氣流的作用下,從除塵器的入口進(jìn)入除塵體,通過(guò)濾筒過(guò)濾作用,粉塵從氣流中分離出來(lái),被凈化了的干凈氣體從濾筒內(nèi)部進(jìn)入凈氣室排出;粉塵經(jīng)過(guò)濾筒過(guò)濾時(shí),粉塵留在濾筒的外表面。

Under the action of negative pressure airflow, dust gas enters the dust removal body from the inlet of the dust collector, and is separated from the airflow through the filtering effect of the filter cartridge. The purified clean gas enters the clean air chamber from the inside of the filter cartridge and is discharged; When dust is filtered through the filter cartridge, it remains on the outer surface of the filter cartridge.

除塵系統(tǒng)-主引風(fēng)機(jī)

Dust removal system - main induced draft fan

風(fēng)機(jī)為國(guó)內(nèi)知名品牌變頻離心風(fēng)機(jī),電機(jī)選用西門(mén)子電機(jī)滿足低壓電機(jī)效率應(yīng)達(dá)到國(guó)家標(biāo)準(zhǔn)《電動(dòng)機(jī)能效限定值及能效等級(jí)》GB 18613-2020,能效等級(jí)2級(jí)及以上水平,帶有減震器保護(hù)設(shè)備,風(fēng)機(jī)進(jìn)出口設(shè)有軟連接避免共振,軟連接采用阻燃材料,外殼為堅(jiān)固的焊接碳鋼板材,做防腐措施。

The fan is a well-known domestic brand variable frequency centrifugal fan, and the motor is selected from Siemens. The efficiency of the low-voltage motor should meet the national standard "Energy Efficiency Limit Values and Energy Efficiency Grades of Electric Motors" GB 18613-2020, with an energy efficiency grade of level 2 or above. It is equipped with shock absorber protection equipment, and the inlet and outlet of the fan are equipped with soft connections to avoid resonance. The soft connections are made of flame-retardant materials, and the shell is a sturdy welded carbon steel plate with anti-corrosion measures.

風(fēng)機(jī)配備有降噪箱,箱體采用外板為Q235碳鋼≥3mm,箱體厚度≥100mm中間加隔音棉,可有效控制噪音,白天≤65dB(A),夜晚≤55dB(A),房體骨架為槽鋼或工字鋼+方管,房體預(yù)留有足夠空間,便于后

The fan is equipped with a noise reduction box, which is made of Q235 carbon steel with an outer plate of ≥ 3mm and a box thickness of ≥ 100mm. Sound insulation cotton is added in the middle to effectively control noise, with a daytime noise level of ≤ 65dB (A) and a nighttime noise level of ≤ 55dB (A). The frame of the room is made of channel steel or I-beam+square tube, and there is sufficient space reserved in the room for easy access

期工人在對(duì)內(nèi)部風(fēng)機(jī)維護(hù),更換電機(jī),便于拆裝。

The workers are maintaining the internal fan and replacing the motor for easy disassembly and assembly.

除塵系統(tǒng)-電控系統(tǒng)

Dust removal system - electrical control system

電控柜采用封閉柜式結(jié)構(gòu)具有良好的接地保護(hù),電器元件選用施耐德/西門(mén)子等知名品牌具有安全強(qiáng)制認(rèn)證標(biāo)識(shí),所有元件標(biāo)識(shí)一一對(duì)應(yīng),布設(shè)合理,整齊美觀,控制電源3×380V/50Hz,防護(hù)等級(jí)為IP21。采用型材骨架,表面噴塑,且容易并柜安裝。電控柜安裝遵照《機(jī)械電氣安全機(jī)械電氣設(shè)備第1部門(mén):通用技術(shù)要求》GB/T5226.1-2019。GB50054-95執(zhí)行。

The electrical control cabinet adopts a closed cabinet structure with good grounding protection. The electrical components are selected from well-known brands such as Schneider/Siemens with mandatory safety certification marks. All component marks correspond one-to-one, and the layout is reasonable, neat and beautiful. The control power supply is 3 × 380V/50Hz, and the protection level is IP21. Adopting profile skeleton, surface spray coating, and easy to install in cabinets. The installation of the electrical control cabinet shall comply with the "Mechanical Electrical Safety - Mechanical Electrical Equipment - Part 1: General Technical Requirements" GB/T5226.1-2019. GB50054-95 shall be implemented.

設(shè)計(jì)依據(jù):《供配電系統(tǒng)設(shè)計(jì)規(guī)范》(GB50052-95)《低壓配電設(shè)計(jì)規(guī)范》(GB50054-95)《通用用電設(shè)備配電設(shè)計(jì)規(guī)范》(GB50055-95)《建筑物防雷設(shè)計(jì)規(guī)范》(GB50057-94 2000年版)《工業(yè)與民用電力裝置的接地設(shè)計(jì)規(guī)范》(GBJ65-83)《電力工程電纜設(shè)計(jì)規(guī)范》(GB50217-94)

Design basis: "Code for Design of Power Supply and Distribution Systems" (GB50052-95), "Code for Design of Low Voltage Power Distribution" (GB50054-95), "Code for Design of Distribution of General Electrical Equipment" (GB50055-95), "Code for Design of Lightning Protection of Buildings" (GB50057-94, 2000 edition), "Code for Design of Grounding of Industrial and Civil Electrical Installations" (GBJ65-83), "Code for Design of Cables in Power Engineering" (GB50217-94)

設(shè)備安全措施-泄爆片

Equipment Safety Measures - Explosion Relief Disc

在異常狀態(tài)下,若出現(xiàn)異常導(dǎo)致壓力劇增,泄爆片會(huì)自動(dòng)泄爆,減少對(duì)系統(tǒng)設(shè)備的損壞。根據(jù)HG/T20570.3《爆破片的設(shè)置和選用》,設(shè)有爆破片裝置,由爆破片和夾持器等裝配組成的壓力泄放安全裝置,當(dāng)爆破片兩側(cè)的壓力差達(dá)到預(yù)定溫度下的預(yù)定值時(shí),爆破片即刻動(dòng)作,泄放出壓力介質(zhì)。

In an abnormal state, if an abnormality occurs and leads to a sharp increase in pressure, the explosion-proof plate will automatically release, reducing damage to the system equipment. According to HG/T20570.3 "Setting and Selection of Bursting Disc", a bursting disc device is installed, which is a pressure relief safety device composed of bursting disc and clamp. When the pressure difference on both sides of the bursting disc reaches the predetermined value at the predetermined temperature, the bursting disc immediately acts to release the pressure medium.

設(shè)備安全措施-火花捕捉器

Equipment safety measures - Spark catcher

火花捕集器機(jī)理(1).篩濾作用(2).慣性碰撞(3).擴(kuò)散作用(4).攔截作用上述各種捕集機(jī)理對(duì)于同一特性的火星來(lái)說(shuō)并非都同時(shí)有效,起主導(dǎo)作用的往往只是一種機(jī)理或二、三種機(jī)理的聯(lián)合作用。其主導(dǎo)作用要根據(jù)火星塵粒性質(zhì),結(jié)構(gòu)、特性和運(yùn)行條件等實(shí)際情況確定。

Spark catcher mechanism (1) Screening function (2) Inertial collision (3) Diffusion effect (4) The various capture mechanisms mentioned above are not all effective for Mars with the same characteristics, and the dominant mechanism is often only one mechanism or a combination of two or three mechanisms. Its dominant role should be determined based on the actual conditions such as the properties, structure, characteristics, and operating conditions of Martian dust particles.

設(shè)備安全措施-自動(dòng)溫感滅火

Equipment safety measures - automatic temperature sensing fire extinguishing

過(guò)濾單元發(fā)生自然異常狀態(tài)時(shí),溫控感應(yīng)器檢測(cè)到溫度異常時(shí)電控系統(tǒng)自動(dòng)停止主引風(fēng)機(jī)運(yùn)行,溫感干粉滅柜開(kāi)啟噴入滅火劑撲滅火源,如果溫感滅火系統(tǒng)發(fā)生故障,過(guò)濾單元內(nèi)部安裝的2套自感型干粉滅火彈,在箱體內(nèi)溫度高于90度時(shí)會(huì)自行開(kāi)啟滅火。

When the temperature sensor detects a natural abnormal state in the filtering unit, the electronic control system automatically stops the operation of the main induced draft fan. The temperature sensing dry powder extinguishing cabinet opens and sprays fire extinguishing agent to extinguish the fire source. If the temperature sensing fire extinguishing system malfunctions, the two sets of self sensing dry powder fire extinguishers installed inside the filtering unit will automatically start extinguishing when the temperature inside the box exceeds 90 degrees.

本文由 車(chē)間整體除塵設(shè)備 友情奉獻(xiàn).更多有關(guān)的知識(shí)請(qǐng)點(diǎn)擊 http://www.9qmv.com/ 真誠(chéng)的態(tài)度.為您提供為全面的服務(wù).更多有關(guān)的知識(shí)我們將會(huì)陸續(xù)向大家奉獻(xiàn).敬請(qǐng)期待.

This article is a friendly contribution from the overall dust removal equipment in the workshop For more related knowledge, please click http://www.9qmv.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

上一篇:車(chē)間整體除塵設(shè)備:從源頭治理到高效設(shè)備的實(shí)戰(zhàn)指南

下一篇:機(jī)器人涂裝線的前處理如何做才能提高效率

魯公網(wǎng)安備 37142502000144號(hào)

魯公網(wǎng)安備 37142502000144號(hào)